All About Flashing

Some areas of roofs and exterior walls are particularly prone to leaks and water damage.

These include roof valleys, the intersection between a dormer wall and the roof surface, skylight perimeters and nearly anywhere runoff is heavy, or where two opposing surfaces meet.

These areas require the extra protection

that Flashing provides.

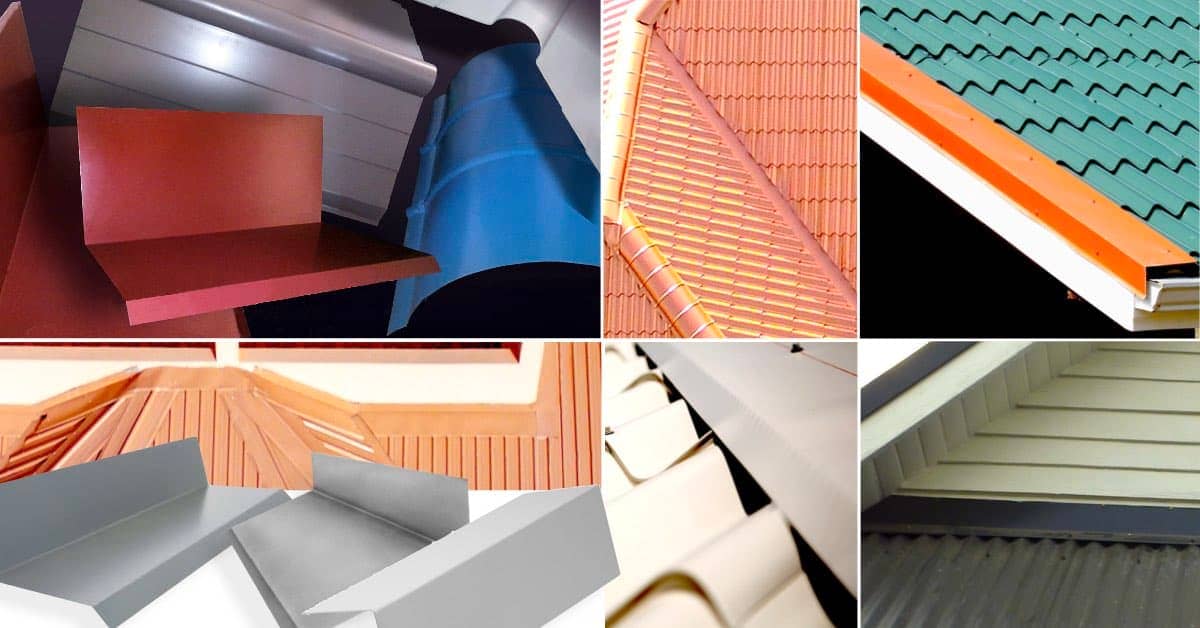

Although roof flashing is occasionally fabricated from plastic, roofing felt, or rubber, it is usually made of rust-resistant metal; galvanised steel, aluminium, or copper. Galvanised sheet metal is most common.

Flashing is formed from flat steel into various shapes, depending upon the job it must do.

The main types of roof flashing handle Roof Valleys, where two roof planes meet, Drip edges preventing water from seeping under roofing along the edges of rakes and eaves, skylights and dormers, where difficult angles meet the main roof sheeting.

They also seal various architectural elements, such as vent pipes, which protrude from the roof surface, often with two or more competing materials.

The combination of universal bat proofing, sealant tape, silicone and other water resistant sealants, assist flashing in creating a long lasting barrier.

Ridge caps are equally part of the flashing family, covering and protecting the join between two or more roof planes, be they at the apex of the roof, or at the each hip of a complex combination of dimensions.

In the world of complex structures with many variables, custom flashing permutations of shape and size are seemingly endless.

But in an average construction, many standard shapes apply, making the roof design do what it's supposed to, protecting the contents of the building from the ravages of the elements, whether water, wind or sunshine.

Flashing, in its best use, serves to control those forces of nature by directing and managing, otherwise uncontrollable wind and water.

Gladly, exposed rafter roof design has given rise to the general use of T111 boarding, as a protective layer and sound barrier, allowing for Plyco® Ply-Foil Roofing Insulation to be placed underneath galvanised roof sheeting. This also gives a firm base for accurate positioning of flashing at various critical points of the roof construction, while not compromising the heat blocking membrane.

At ECMIL we are extremely experienced in finding the right size, shape, function and structure of all of your flashing requirements.

Once you provide us with your roof drawings and elevations, we will calculate all of your requirements and work with you, or your architect, to supply the best possible combination of flashing, matched perfectly in colour and style to your sheet profile, adding durability to your roof installation.

Contact your ECMIL sales representative today

and discover how quality Flashing will protect your home.

NB. This article is for general information purposes only and is meant as an incentive to the reader, who should then research and seek advice from their architectural and construction professionals to confirm that the ideas expressed are possible within the building codes of their territory or within the limitations of their home's architecture. ECMIL only recommends their own products and third party products which they supply, as part of their company's roofing solutions to customers.